A method frequently referred to as the progressive metal stamping process is the precision metal stamping process. It is a well-known method for processing and producing hardware. It makes it possible to create a variety of precision components that would otherwise be impossible to produce in the sector in a way that is both times- and cost-effective. For example, the technique of precision metal stamping is a technology that manufacturers often use in a wide variety of equipment applications. This article provides a comprehensive analysis of the stamping process’s merits and capabilities, aiming to ensure that anybody interested in precision automotive metal stamping may reap the benefits of this option.

What Exactly Is Meant By The Term Precision Metal Stamping?

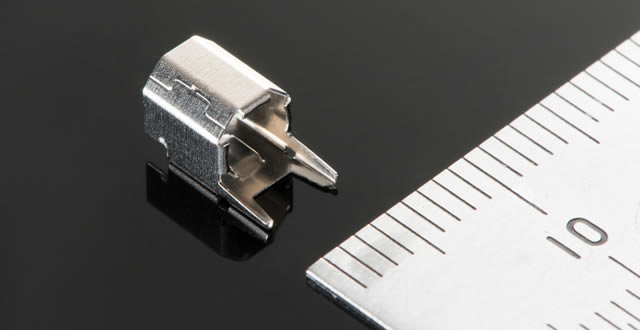

During this operation, equipment equipped with dies is used to transform sheets of metal into the desired bespoke forms while maintaining exceedingly precise tolerances. The manufacturer can finish producing these workpieces with only one stroke of the press; this is referred to as a single-stage operation.

For more complicated pieces, it may be necessary to make repeated strokes, referred to as a serial operation. However, the precise metal stamping process is adaptive and flexible, making it particularly well-suited for batch manufacturing.

The high precision level is distinct from other machining methods, even when applied to pieces with a complicated design. For example, even the tiniest mistake might make the finished product unusable; producers need precision metal stamping presses to do microstamping and create complicated little components.

The accuracy and efficiency of precision metal stamping, which is used to manufacture these components, fulfill the stringent standards placed on stamping parts by the aerospace sector and the automobile industry.

Computer modeling and virtual simulation of the stamping process are often the first steps in precision metal stamping projects. These steps check for mistakes or flaws in the stamping process. Following the conclusion of the test, the computer will transmit the design to the machine to minimize the impact of human mistakes.

As a business, Hashimoto Precision specializes in producing precision metal stamping components. Customers are satisfied with stamped metal components due to their adaptability to client specifications and tight dimensional tolerances.

Pagalmusiq.com Popular News Update Website | Pagalmusiq.com

Pagalmusiq.com Popular News Update Website | Pagalmusiq.com