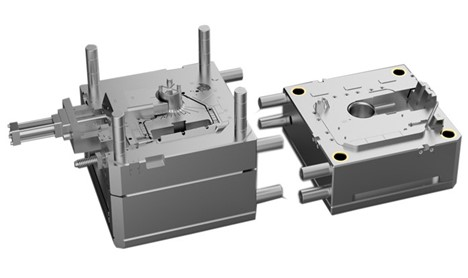

The application range of plastic injection molds is becoming more and more extensive. Many enterprises will choose plastic injection molds to process and customize to develop new products. Please professional design teams to customize plastic injection molds for their enterprises. This requires choosing a powerful manufacturer of plastic injection mold processing customization. So, what are the advantages of plastic injection mold processing customization?

-

Customize the mold according to the needs

Enterprises can customize plastic injection mold processing according to their own needs. The current market competition is fierce, and there are more homogeneous products. To win in the fierce market competition, many companies are developing new products. The research and development of new products need to be customized for injection molds. Of course, some companies have their R&D teams. They hand over the design drawings of new products to injection mold manufacturers. The mold manufacturers design molds according to the design drawings of new products and then process and produce them. Such tailor-made plastic injection molds are unique. Future products will have certain competitiveness in the market. However, suppose the company has developed a new product. In that case, it must apply for a patent for its new product before the design and processing of plastic injection molds so as to prevent the new product developed by itself from being misappropriated by others. This is a kind of protection for the enterprise and a measure for R&D patents.

-

Select the appropriate material according to the needs

There are many kinds of materials for plastic injection molds. Enterprises and manufacturers cooperate to customize plastic injection molds. Manufacturers can choose suitable materials according to their requirements, ensuring the quality of injection molds and the quality of future products. At the same time, it will increase the Service life of plastic injection molds. Although choosing plastic injection materials by yourself will increase the cost of the mold, if your product is mass-produced, a qualified, high-quality plastic injection mold is very necessary.

-

The precision of plastic injection molds is higher

Of course, the more accurate the plastic injection mold, the better. Enterprises and manufacturers can directly process and customize plastic injection molds to better grasp the accuracy. Manufacturers make good designs. Many times, companies directly purchase plastic injection molds from the market, whether in terms of material, accuracy, or service life, there are defects of one kind or another. For future products, it is better for enterprises to choose and customize molds from manufacturers.

Customized processing of plastic injection molds is now a trend, and more and more companies are choosing this way to cooperate with manufacturers to customize plastic injection molds according to their own needs. Of course, when choosing a manufacturer, an enterprise should also choose a strong manufacturer. It must not choose a manufacturer with poor strength and poor service because of the price. Such a manufacturer will make you regret it except for the price.

Conclusion

ABERY is a manufacturer specializing in plastic injection molds. It has a professional design team, excellent production procedures, and a professional management team, and its service concept and business philosophy are consumer-concentric. A good plastic injection mold provides better service, allowing you to choose once and trust for a lifetime. If you are looking for a custom manufacturer of plastic injection mold processing, you may wish to click on ABERY to consult and have a look. I believe it will surprise you and give you trust.

Pagalmusiq.com Popular News Update Website | Pagalmusiq.com

Pagalmusiq.com Popular News Update Website | Pagalmusiq.com